Choosing the right metal roofing material is essential for builders due to several factors such as durability, energy efficiency, and appearance. The durability of the metal roofing material ensures that it can withstand harsh weather conditions, thereby prolonging the lifespan of the roof and reducing long-term maintenance costs. Additionally, the energy efficiency of the material can contribute to lower heating and cooling costs, making it an environmentally friendly and cost-effective choice.

When comparing Galvalume steel and aluminum, both have their own benefits and drawbacks. Galvalume steel is known for its excellent corrosion resistance and is a popular choice for areas with high humidity or salt air. On the other hand, aluminum is lightweight and naturally resistant to corrosion, making it a great option for coastal regions.

Considerations to take into account when deciding between the two materials include cost, maintenance, and longevity. Galvalume steel typically has a lower initial cost, but may require more maintenance over time, while aluminum is more expensive upfront but requires minimal maintenance and has a longer lifespan.

In conclusion, selecting the right metal roofing material is crucial for builders as it can impact the overall durability, energy efficiency, and appearance of the building. It is important to carefully consider the specific needs and requirements of the project before making a decision.

Galvanized steel is a widely used material in the construction and manufacturing industries due to its durability and corrosion resistance. This overview will explore the process of galvanization, the various applications of galvanized steel, and the advantages it offers in different environments. Additionally, we will discuss the different types of galvanized steel, such as hot-dip galvanized and electro-galvanized, and the differences between them. Furthermore, we will delve into the environmental impact of galvanized steel and its recyclability, as well as tips for proper maintenance to ensure its longevity. Whether you are a professional in the industry or simply interested in learning more about this versatile material, this overview will provide you with valuable insights into the world of galvanized steel.

Galvanized steel is a type of steel that has been coated with a layer of zinc through a process called galvanization. This process involves immersing the steel in a bath of molten zinc, which forms a protective layer over the surface of the steel. The zinc coating serves as a barrier, protecting the underlying steel from corrosion and rust. The typical composition of the zinc coating on galvanized steel is approximately 98% zinc and 2% other metals.

In contrast, ZINCALUME® steel is coated with a combination of aluminum, zinc, and silicon, which provides enhanced corrosion resistance and longevity compared to traditional galvanized steel.

The key advantages of galvanized steel include its resistance to corrosion, durability, and low maintenance requirements. This makes it suitable for a wide range of applications across various industries, including construction, automotive, electrical, and agricultural sectors. Galvanized steel is commonly used in the production of roofing and siding materials, automotive parts, and agricultural equipment due to its protective properties and longevity.

Galvanizing steel is a process of applying a protective layer of zinc to the surface of the steel to prevent corrosion. There are two main methods used for galvanizing steel: immersion and electroplating. In the immersion method, the steel is dipped into a bath of molten zinc, allowing the zinc to adhere to the surface of the steel. In electroplating, an electric current is used to deposit the zinc onto the steel, creating a more uniform and controlled coating.

The zinc coating acts as a sacrificial layer, meaning that it will corrode before the steel does. This protects the underlying steel from rust and corrosion, significantly extending its lifespan. This makes galvanized steel highly durable and resistant to the elements.

The benefits of galvanized steel include cost efficiency, as it requires minimal maintenance and has a long lifespan. It is also incredibly strong and can withstand harsh environmental conditions. Additionally, galvanized steel is a recyclable material, making it an environmentally friendly choice for construction and manufacturing.

In conclusion, galvanizing steel through immersion or electroplating with a zinc coating provides superior protection against corrosion, making it a highly desirable material for various applications.

Galvanized steel offers numerous benefits for construction projects. Its cost efficiency is evident in its longevity and low maintenance requirements. The protective zinc coating on galvanized steel provides excellent resistance to rust, making it a durable and reliable choice for outdoor structures.

Although the initial purchase price of galvanized steel may be slightly higher than other materials, it offers better value for money over the long-term due to its extended lifespan and minimal maintenance needs. This makes it a cost-effective option for construction projects in the long run.

Various outdoor-living products such as fences, gates, and railings, as well as roofing materials, utilize galvanized steel due to its superior corrosion resistance. It is an ideal choice for outdoor applications, offering protection against harsh weather conditions and ensuring the longevity of the structure.

In conclusion, the use of galvanized steel in construction projects is a wise investment. Its cost efficiency, longevity, protective coating, and resistance to rust make it a reliable and durable choice for a wide range of applications, offering better value for money in the long-term.

Aluminum is a widely used metal known for its versatility, lightweight properties, and resistance to corrosion. This abundant element is commonly found in the earth's crust and has a wide range of applications in various industries, including construction, transportation, aerospace, and packaging. It is highly sought after for its strength-to-weight ratio, making it ideal for use in the production of vehicles, aircraft, and structural components. Additionally, aluminum is easily recyclable, making it a sustainable option for many manufacturing processes. In this overview, we will explore the properties, uses, and significance of aluminum in today's global market.

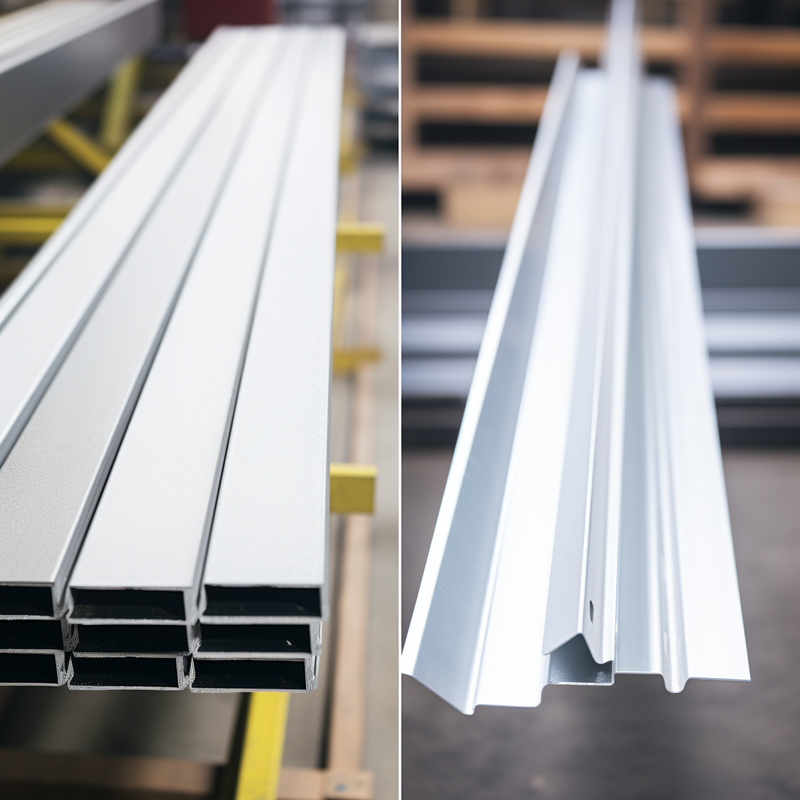

Aluminum roofing is a type of roofing material made from aluminum, a lightweight and malleable metal that is known for its corrosion-resistant properties. This makes it an ideal choice for use in coastal climates, where saltwater air can cause corrosion in other types of roofing materials.

Another key property of aluminum roofing is its exceptional durability and long lifespan. It can withstand harsh weather conditions, including high winds and heavy rainfall, without deteriorating. This longevity makes it a cost-effective option for homeowners and businesses looking for a low-maintenance roofing solution.

In recent years, aluminum roofing has become increasingly popular due to its lightweight nature, which makes it easier to install and transport. It also offers a modern and sleek aesthetic that appeals to many homeowners and building owners.

In conclusion, aluminum roofing is a practical and durable choice for those living in coastal areas or anyone looking for a low-maintenance, long-lasting roofing solution. Its lightweight, corrosion-resistant properties, and increasing popularity make it a top choice for many.

Aluminum roofing offers several advantages that make it a popular choice for residential and commercial buildings. One of the main benefits of aluminum roofing is its exceptional corrosion resistance. Unlike other metals, aluminum does not rust, making it an ideal choice for areas with high moisture or salt exposure, such as coastal regions. This inherent resistance to rust and corrosion ensures that the roof remains durable and maintenance-free for many years.

Additionally, aluminum is extremely lightweight, making it easier to install and reducing the overall load on the structure. This can be especially beneficial for older buildings that may not be able to support the weight of heavier roofing materials. Furthermore, aluminum roofs have a long lifespan of 40-60 years, significantly outlasting other roofing materials. This means that once installed, an aluminum roof will provide long-term protection and performance with minimal maintenance.

In conclusion, aluminum roofing is the best choice for areas with high moisture or salt exposure due to its corrosion resistance. Its lightweight nature and long lifespan make it a cost-effective and durable option for any building.

When it comes to choosing the right material for construction and manufacturing, galvanized steel and aluminum are two popular choices. Both materials have their own unique characteristics and benefits, making them suitable for a variety of applications. In this comparison, we will take a closer look at the key differences between galvanized steel and aluminum, including their properties, durability, corrosion resistance, cost, and environmental impact. By understanding the advantages and disadvantages of each material, you can make an informed decision about which option is best for your specific needs.

Corrosion resistance in metals such as steel and aluminum can be enhanced through various methods such as using stainless steel alloys, zinc plating, and powder coating.

Stainless steel alloys, such as 316 stainless steel, are extremely corrosion resistant due to the addition of molybdenum. They are ideal for use in harsh environments where corrosion is a significant concern. However, stainless steel can be expensive and may not be suitable for all applications.

Zinc plating involves applying a thin layer of zinc to the surface of the metal. This provides effective corrosion protection as the zinc layer sacrificially corrodes instead of the base metal. Zinc plating is cost-effective and widely used in the automotive and construction industries.

Powder coating involves applying a dry powder to the metal surface and then curing it to form a protective layer. It provides excellent corrosion resistance and is also environmentally friendly. However, it may not be as effective in high-temperature or abrasive environments.

Each method has its own advantages and trade-offs in relation to corrosion resistance. The choice of method will depend on the specific application and the environmental conditions the metal will be exposed to.